our

products

-

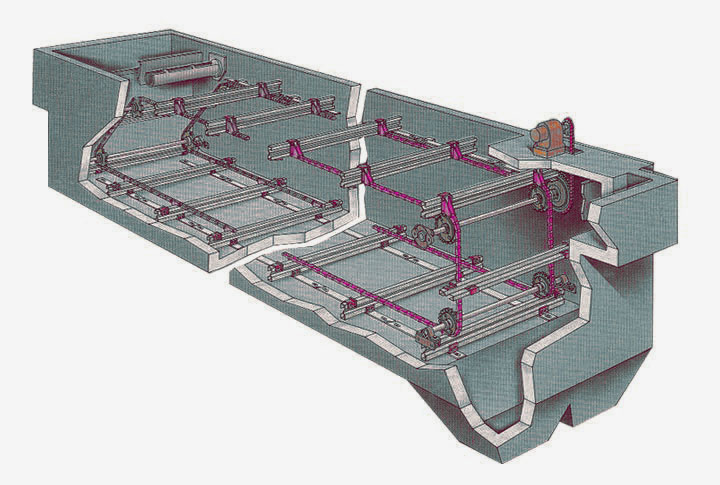

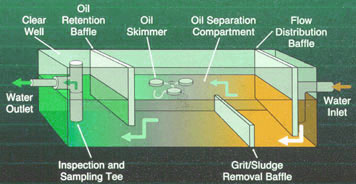

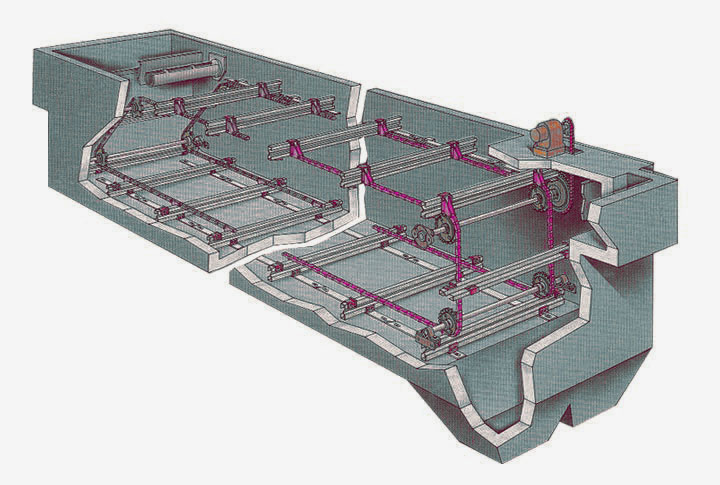

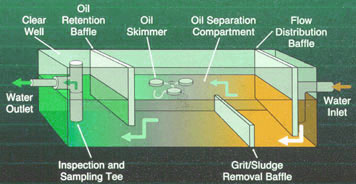

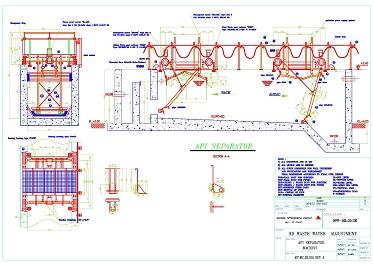

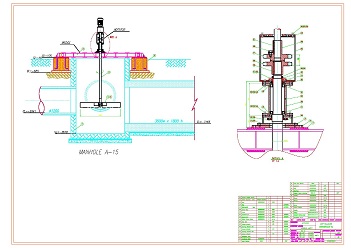

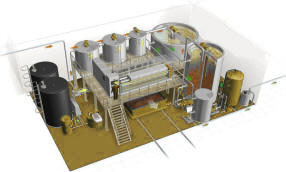

API oil separator machine

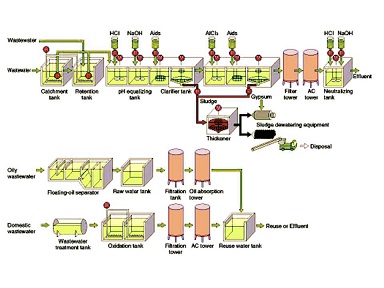

Api separator machine is a machine for separate oil from wastewater , this

machine move over water pool and collect oil from water

API oil water separator is physical separation systems designed for removal of oils, fuels, hydraulic fluids products from water. The API separator is designed per American Petroleum Institute (API) standards for above and below grade applications.

The API separator is a gravity separation device . The design of the separator is based on the specific gravity difference between the oil and the wastewater because that difference is much smaller than the specific gravity difference between the suspended solids and water. Based on that design criterion, most of the suspended solids will settle to the bottom of the separator as a sediment layer, the oil will rise to top of the separator, and the wastewater will be the middle layer between the oil on top and the solids on the bottom .

Typically, the oil layer is skimmed off and subsequently re-processed or disposed of, and the bottom sediment layer is removed by a chain and flight scraper and a sludge pump. The water layer is sent to further treatment consisting usually of a dissolved air flotation unit for further removal of any residual oil and then to some type of biological treatment unit for removal of undesirable dissolved chemical compounds.

|

|

|

|

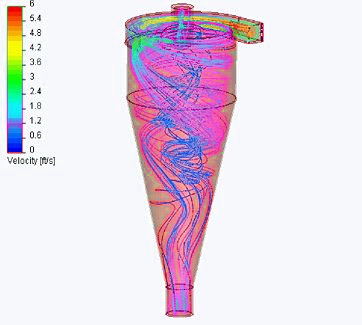

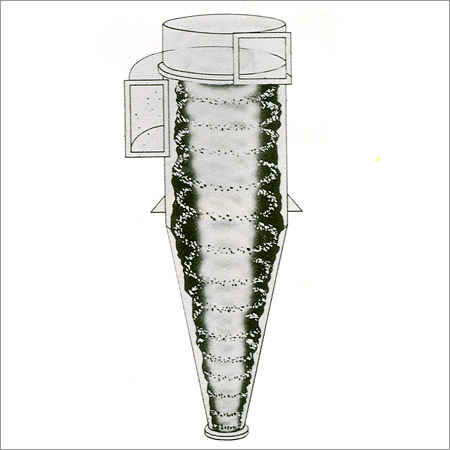

cyclone separator

Cyclonic separation is a method of removing particulates from an air, gas or liquid stream, without the use of filters, through vortex separation. Rotational effects and gravity are used to separate mixtures of solids and fluids.

A high speed rotating flow is established within a cylindrical or conical container called a cyclone. flows in a helical pattern, beginning at the top (wide end) of the cyclone and ending at the bottom (narrow) end before exiting the cyclone in a straight stream through the center of the cyclone and out the top. Larger (denser) particles in the rotating stream have too much inertia to follow the tight curve of the stream, and strike the outside wall, then falling to the bottom of the cyclone where they can be removed. In a conical system, as the rotating flow moves towards the narrow end of the cyclone, the rotational radius of the stream is reduced, thus separating smaller and smaller particles.

|

|

|

screen

We manufacture, distribute, and fabricate wire mesh, hardware cloth, wire cloth, stainless steel wire mesh, stainless steel wire mesh screen discs,screen wire, copper wire mesh, copper screen, welded wire meshes, specialty insect screens, bronze screen,brass screens, welded wire mesh fabric, wire screen and screen mesh, brass mesh, bronze mesh, micronic mesh, sintered wire mesh laminates, slitting services , filter discs

|

|

|

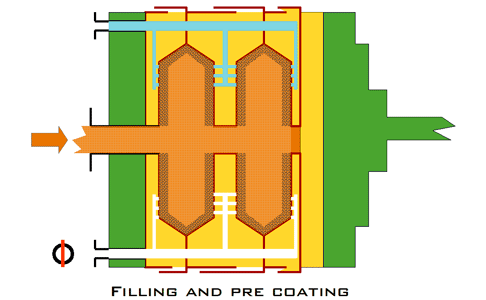

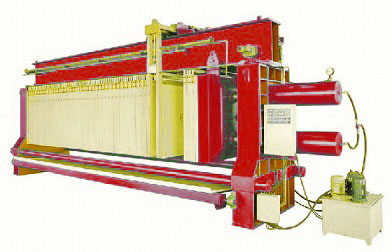

filter press

A filter press is a liquid-solid separation device used to reduce the volume and weight of a slurry waste or process stream by separating liquid filtrate and solid filter cake. The operation of a filter press is therefore a batch process. Depending on the particular application, the filter press may be used to recover either the solid particulate, the liquid stream, or both.

|

|

|

mixer

Mixers agitators are being used in industrial water and wastewater treatment plants. mixers are being used in the following applications:- Rapid and Flash Mixing

- Flocculation - Lime and Chemical Makeup - Activated Carbon Slurry Mixing - Digestion - Equalization and Neutralization

Our experience in wastewater treatment helps us achieve optimal process results.

|

|

|

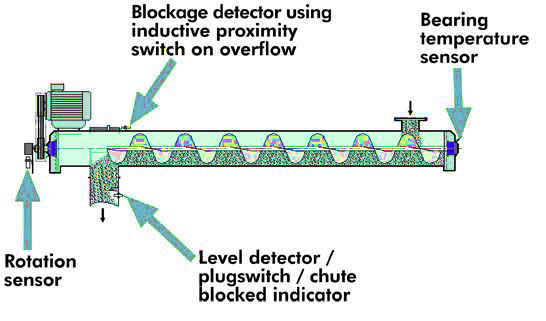

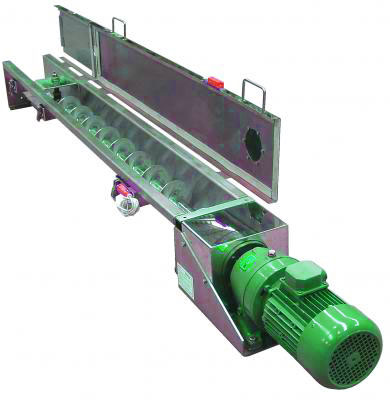

screw

conveyer

They usually consist of a trough or tube containing either a spiral blade coiled around a shaft, driven at one end and held at the other, driven at one end and free at the other. The rate of volume transfer is proportional to the rotation rate of the shaft. In industrial control applications the device is often used as a variable rate feeder by varying the rotation rate of the shaft to deliver a measured rate or quantity of material into a process.

Screw conveyors can be operated with the flow of material inclined upward. When space allows, this is a very economical method of elevating and conveying. As the angle of inclination increases, the capacity of a given unit rapidly decreases.

|

|

|

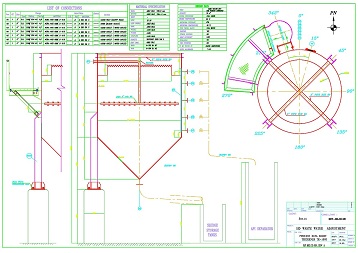

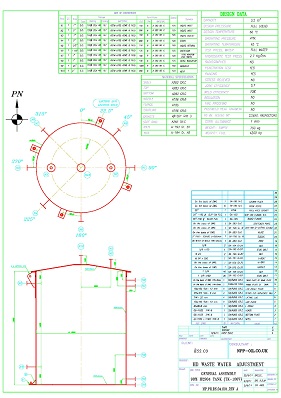

tank

( carbon steel , pvc + frp , stainless steel , rubber lining , PFA

lining )

you can benefit of our best desgn ,

|

|

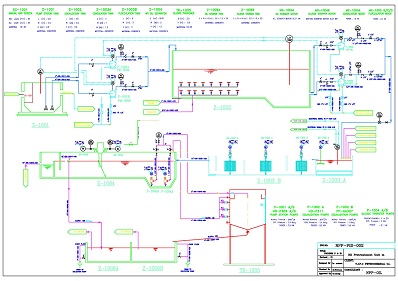

- injection system ( HCL , H2SO4 , NAOH , PAC )

injection section is one of the most important part of waste water tratment plant

we alwayes need to control PH , CONDUTIVITY , TURBULANCY ,... , this will need online analayse and atomatic injection system

our control system is product of company like ABB , YOKOGAWA , YAMATEK ,... , all controller , DCS system , analayser , ... selected by our enginearing according to project detail

|

|

|